Drivetrain development What motivates us: The realisation of an environment-friendly motor vehicle.

The development of innovative drive concepts is essential for the future of the automobile. Electric drives and hybrid drives will supplement the classical combustion engines.

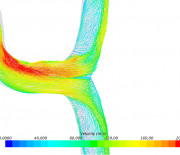

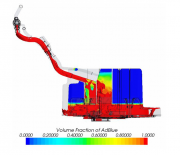

The careful use of natural resources as well as the considerable reduction of contaminants of vehicles are among the most important tasks. FES/AES is your best strategic partner for alternative approaches due to our long-lasting experience in the competence areas of exhaust systems, SCR tank systems and electric mobility.

Using efficient development processes, we work in a customer-oriented and targeted way, towards your ideas and tasks. Our performance scope begins with first feasibility studies or concepts, and reaches up to the integration of the drive into the vehicle.

A one-stop service.

The following skills are unified in drive system development area:

Your contact in the drive system and electric mobility development area:

-

Hartmut SchimmelExhaust gas system and SCR tank system development

Hartmut SchimmelExhaust gas system and SCR tank system development -

Torsten FlammigerElectric mobility development area

Torsten FlammigerElectric mobility development area -

Please send your inquiry

via e-mail to:> info@fes-aes.de

Your message will be forwarded to the responsible department immediately.

For telephone inquiries, please call our center:Tel.: +49 375 5660-0

Any questions on this area of services?We will answer you gladly.