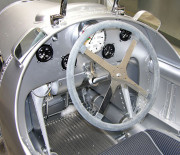

Prototyping What we create: Tailored components and car bodies.

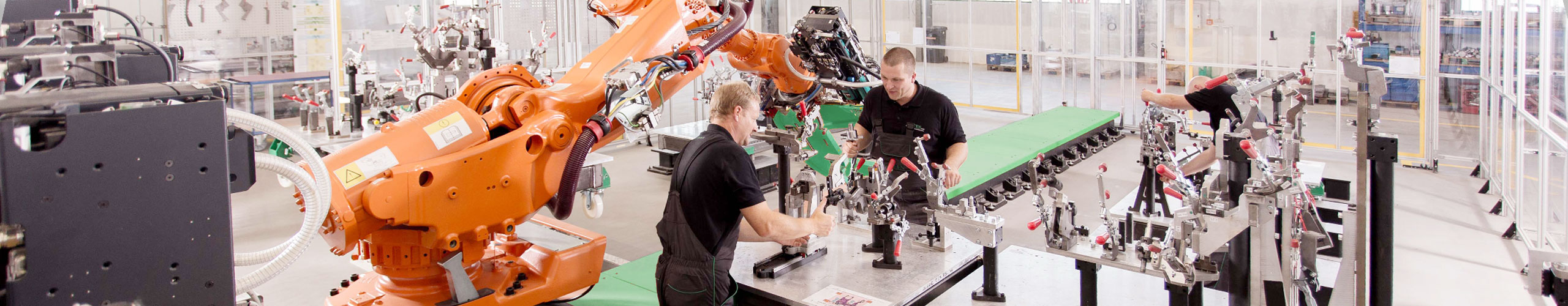

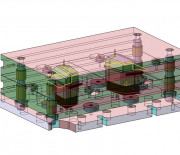

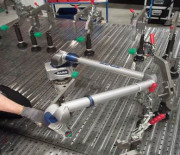

Our construction department creates well-thought prototypes from development studies and ideas. Equipped with the cutting-edge manufacturing technologies, about 95 employees work on a production surface of 11,600 m². Production is performed order-related either manually for individual components, or automated for small series.

Besides the construction of concept car bodies or vehicle components, our competences cover the manufacturing of sheet metal parts and milled parts. We are familiar with the automotive, railway and aerospace industry.

We have the following skills in the area of prototype construction:

Your contact in prototype construction:

-

We have cutting-edge manufacturing technologies.Erik SchwarzenbergHead of Prototype Construction

We have cutting-edge manufacturing technologies.Erik SchwarzenbergHead of Prototype Construction -

Please send your inquiry

via e-mail to:

> info@fes-aes.deYour message will be forwarded to the responsible department immediately.

For telephone inquiries, please call our center:Tel.: +49 375 5660-0

Any questions on this area of services?We will answer you gladly.

Proven quality

The Prototype Construction Department is certified according to DIN EN 15085-2 and DIN EN ISO 3834-2.

By this our department proves the competence for welding work at rail vehicles and rail vehicle parts

Having reached the highest certification level CL1, we are able the process also parts with high safety relevance.

-

Certification according to DIN EN 15085-2 EN ISO 3834-2 (Prototype Construction Department)Certification according to DIN EN 15085-2 EN ISO 3834-2 (Prototype Construction Department)

The welding processes in rail vehicle construction follow special quality specifications.

The certifications according to DIN EN ISO 3834-2 and DIN EN 15085-2 prove our competence for welding work at rail vehicles and rail vehicle parts.

Having reached the highest certification level CL1, we are able the process also parts with high safety relevance.The required extensive quality management measures have been introduced and are implemented within the processes.