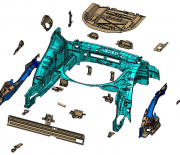

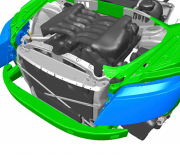

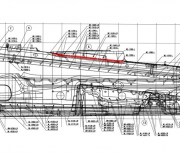

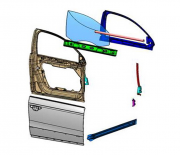

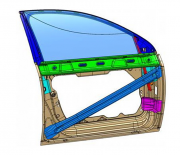

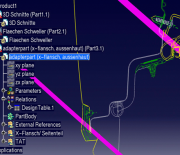

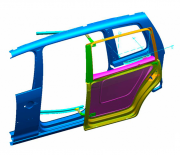

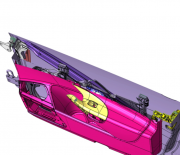

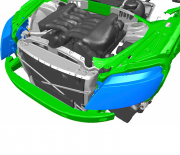

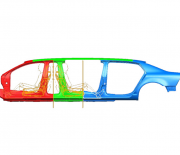

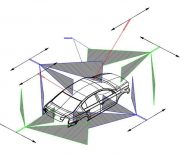

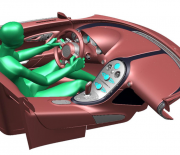

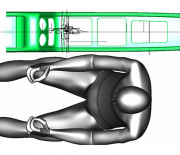

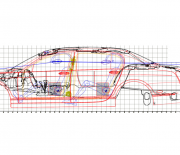

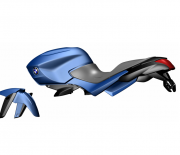

Car body development What moves us. The use of future-oriented materials.

A car body is marked by a high degree of complexity and automation. Our qualified staff offers you vast

knowledge about procedures and processes in order to fulfill your requirements completely and to deliver

the perfect complete solution to you.

Our core skills in the car body development area:

-

Please send your inquiry

via e-mail to:

> info@fes-aes.de

Your message will be forwarded to the responsible department immediately.

For telephone inquiries, please call our center:Tel.: +49 375 5660-0

Any questions on this area of services?We will answer you gladly. -

Sandy MeyerHead of car body development